RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers one of the most robust lineups of filling technologies in the world, with a complete range of solutions that can fill liquid and viscous food, beverage, dairy, pharmaceutical, personal care, chemical, household, and industrial goods products into a variety of rigid containers. With our broad range of filling capabilities, we can partner with customers to help them choose the best solution for their unique application needs each and every time.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn morePRODUCT BENEFITS

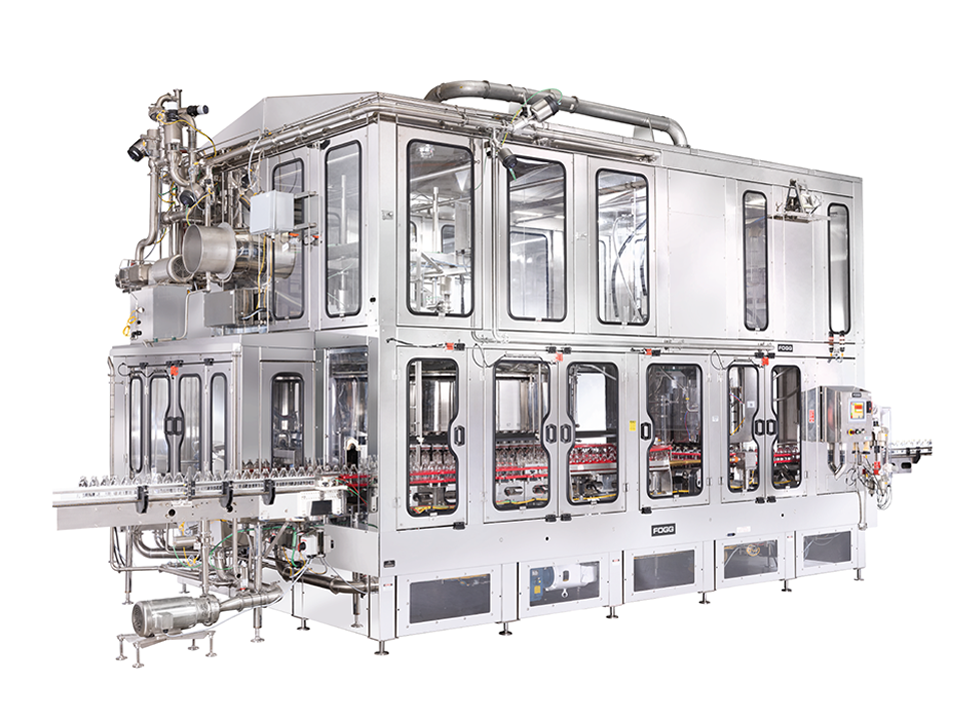

- Exceptional Filling TechnologyThanks to pressure filling technology and precise temperature control, this machine ensures consistent fill levels with minimal product waste, even at high speeds.

- Enhanced Product QualityReduced foam production and contact bottle filling maintain the integrity of your product, ensuring a clean, professional appearance and minimizing contamination risks.

- Effortless High-Speed OperationsDesigned for simplicity and efficiency, this machine’s easy-to-operate interface handles high-speed filling demands, maximizing productivity while reducing downtime.